This is part of a series of posts about manure management on a small horse property (the property is small, not the horse…)

I’m going to interrupt my series on selecting a manure management system to delve into some of the reasons compost is so important, and add some reasons you may want to consider compost production as the manure management method you select.

Let’s start with a little lesson on soils. For a while, I considered becoming a landscape designer, and as part of the program I took a soils class. I learned that soil (it is NEVER called “dirt”, which is what gets under your fingernails) has both texture and structure. Texture refers to the relative volumes of sand, silt and clay in the soil. These are inorganic materials and have different characteristics.

Sand is the largest particle and is generally round or angular. It has large air spaces that improve aeration, but does not hold water or nutrients well.

Silt is a mid-sized particle. It feels like flour when dry and velvety when wet. It holds water and nutrients well. Like sand, its shape is round or angular

Clay is the smallest size particle. Clay particles tend to be flat. They stick together and do not provide good aeration. It does hold water and nutrients well. Clay forms hard clumps when dry and is sticky when wet.

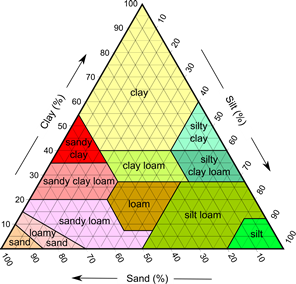

The percentage of each of these 3 particles in the soil determine the soil texture. There is a Textural Triangle that tells you what type of soil you have based on these percentages. This is based only on the content of sand, silt and clay and ignores any other components of a soil. Here’s the USDA Textural Triangle:

The soil tends to be very sandy where I live. When I was buying the property, a new well needed to be drilled. When you drill a well, you end up with quite a lot of soil, called “tailings”, that is removed during the drilling process. Those tailings need to go somewhere, and in my case they got dumped in what is now part of my garden. That included an impressive amount of clay that was from a layer below the typical sandy soil.

I thought, no problem, we have a lot of sand, the clay will just balance it out, right? WRONG! It doesn’t work that way. Meanwhile, I have a slimy mess in that part of the garden.

A few years later, I found myself in the soils class, and asked the instructor why mixing the sand and the clay didn’t result in some beautiful improved soil mix. That’s where soil structure entered the picture. Soil structure is the way sand, silt and clay form aggregates through a variety of processes and result in a variety of shapes. In my case, I basically got sandstone.

Soil consists of more than sand, silt and clay. Those just determine what soil type you have. In addition, you have water, air spaces and organic matter. When I asked my instructor how to improve my soil, the answer was—add organic matter. Adding organic matter will improve almost any soil. It improves aeration and the ability to hold nutrients, and generally makes it more workable. Guess what compost is? Yep-organic matter. And if you have horses on your property and are dealing with the poop that goes along with that, you have the raw ingredients to magically improve your soil.

Organic matter eventually breaks down and is consumed, unlike the inorganic components of sand, silt and clay, so it needs to be continually replenished. And your horses are happy to oblige. So with a good system of composting horse manure, you can keep your soil happy, healthy, and usable now and in the future.

It is now Spring after a year of heavy rain. I’m finally able to get out in the yard and tackle the weeds. And of course, I started in what is still a clay mud pit. Each weed I pulled came up with a sucking sound and a couple pounds of mud. The area was a sulky blue-gray color and slippery. I trundled off with a wheelbarrow to the one fully composted pile in the pasture and started incorporating organic material into the sticky clay. It’s going to need a lot more, and fortunately more is in the works. But my motivation to install a better composting system that will result in faster production of higher-quality compost has gotten a new boost.